Experts in laser plastic welding

Learn about our laser plastic welding processExperts in laser plastic welding

Learn about our laser plastic welding processNewsroom

Innovative solutions for every requirement

Joining Partners

- LT: Transparent Joining Partner

- LA: Absorbing joining partner

Assembly Condition

- Joining partners are pre-assembled

Principle

- Laser energy is passing through LT joining partner and hits welding rib on LA part

- Rib is melted directly by laser

- Through heat transfer, LT joining partner is also melted thus a material combination is created in contact zone of the two joining partners

Joining Partners

- LA1: Absorbing joining partner 1

- LA2: Absorbing joining partner 2

Assembly Condition

- Joining partners are positioned in single nests

- Both joining partners have a welding rib

Principle

- Laser energy is directly applied to the welding ribs and melts both ribs (one or more lasers are used)

- Ribs are melted directly by laser

- When melted, Laser(s) are turned off and joining partners are pressed together with defined force

Joining Partners

- LT1: Transparent Joining Partner 1

- LT2: Transparent Joining Partner 2

Assembly Condition

- Joining partners are pre-assembled

Principle

- Laser energy is passing through BOTH joining partners while a certain amount of energy is being absorbed in both joining partners and melts both materials

- In the contact zone between the two melted joining partners, the material combines thus a welding is created

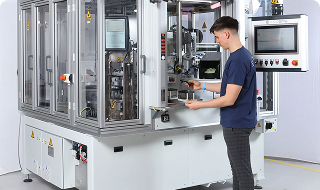

Benefit from our many years of experience

in laser plastic welding

We have the necessary process and market expertise

We accompany you from sampling to series production

We provide you with support throughout the entire service life of our systems.

Cooperative and transparent collaboration guarantees your success

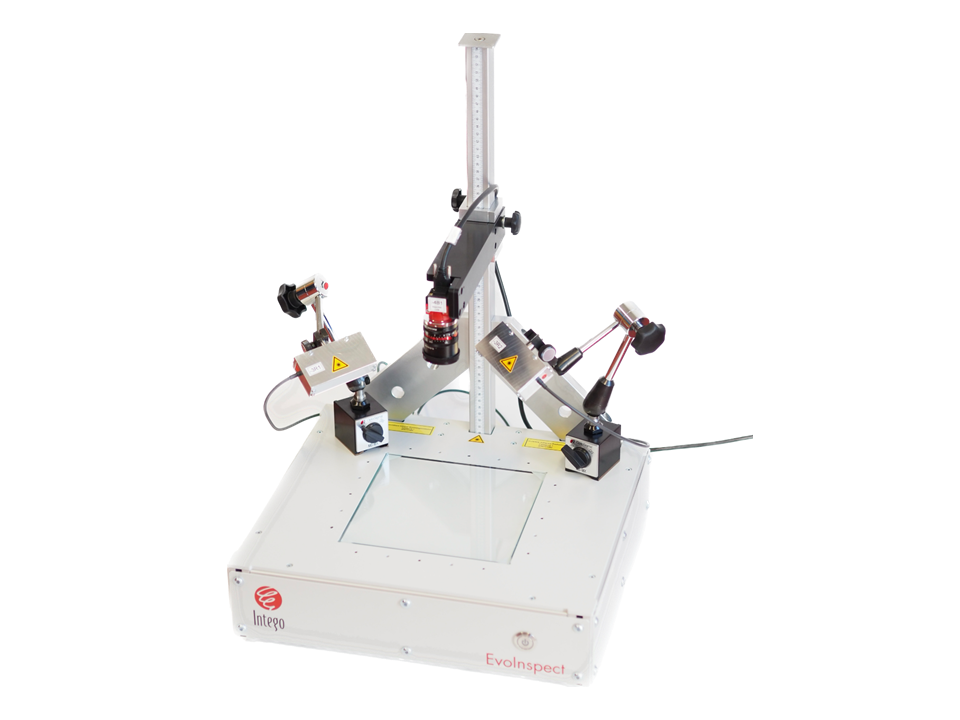

Our services in the field of laser plastic welding

Laser plastic welding is the ideal joining process when plastic parts need to be joined together reliably and with high process consistency.

It is characterized by high precision and precisely controllable energy input. Furthermore, it is a very clean and therefore environmentally friendly joining process. We offer you a comprehensive portfolio to bring this optical technology into your production.

Contact us now!

We are happy to provide you with further information, individual advice, or answer any questions you may have. Please use the contact form—we will get back to you as soon as possible.

Tel.: +49 9131 – 4088 – 0

info@evosys-laser.com

Felix-Klein-Straße 75,

D-91058 Erlangen

D-91058 Erlangen

Contact

"*" indicates required fields