News

EVOSYS honored with the BAYERNS BEST 50 award

Evosys Laser GmbH from Erlangen has once again been awarded the “BAYERNS BEST 50” prize. The award is presented annually by the Bavarian State Ministry of Economic Affairs, Regional Development, and Energy to the 50 fastest-growing medium-sized companies in Bavaria. Erlangen, July 2025: EVOSYS Laser GmbH develops, manufactures, and markets systems for laser material processing…

EVOSYS presents innovative laser welding solutions and developments at the K 2025 trade fair

At this year’s K trade fair, the world’s leading supplier for laser plastic welding will be presenting the latest technologies such as the Evo2Step process and absorption measurement. Interested visitors can also look forward to many innovations to proven products. Erlangen, July 2025: Evosys Laser GmbH will be exhibiting at the K trade fair in Düsseldorf from October…

New contract module with 24/7 service support

With our new contract module, we can guarantee you continuous support for your laser welding systems and minimise the risk of downtimes – around the clock within the area of responsibility of Evosys Laser Services GmbH. The associated Risks Downtime in production is not only annoying, but often also costly. In highly automated production processes…

Meet EVOSYS in Munich!

Next week, you will find us at two industry events in Munich – both at automatica and at the Laser World of Photonics, which is taking place at the same time. At both trade fairs, we will be showing you our solutions for laser welding plastic parts and will be happy to advise you personally…

Laser welding of polymer foils with spatially adapted intensity distributions

Absorber-free laser transmission welding enables the precise and clean joining of plastic films without additives or adhesives. It is therefore particularly relevant for demanding applications in medical technology, optics and the food industry. Laser beams with spatially adapted intensity distribution can be used to enlarge the process window when welding films and increase the weld…

Beam shaping meets laser plastic welding

Next-Gen beam shaper from Midel Photonics enables laser welding of complex plastics in Evosys systems. Evosys and Midel Photonics have collaborated to develop a welding process for high-performance plastics and engineering thermoplastics. Challenge In the automotive industry, the demand for complex plastic components is increasing – for example for fluid lines in electric vehicles. These…

Evosys Laser GmbH celebrates 10th anniversary

A decade full of innovation and growth Erlangen, May 2025: Evosys Laser GmbH proudly celebrates its 10th anniversary as a leading company in laser plastic welding joining technology. Under the creative artificial word “Evosys”, a combination of “Evolution” and “Systems”, the search for the perfect identity that has characterized the company since its foundation began…

Innovative laser welding of transparent films: Highest quality and flexibility for demanding applications

Evosys meets these challenges with an innovative process for laser welding transparent films that does not require the use of additional absorbers. This advanced process not only enables plastic films to be joined efficiently, but also offers a wide range of customization options for different design and tightness requirements. Laser welding of transparent films Our…

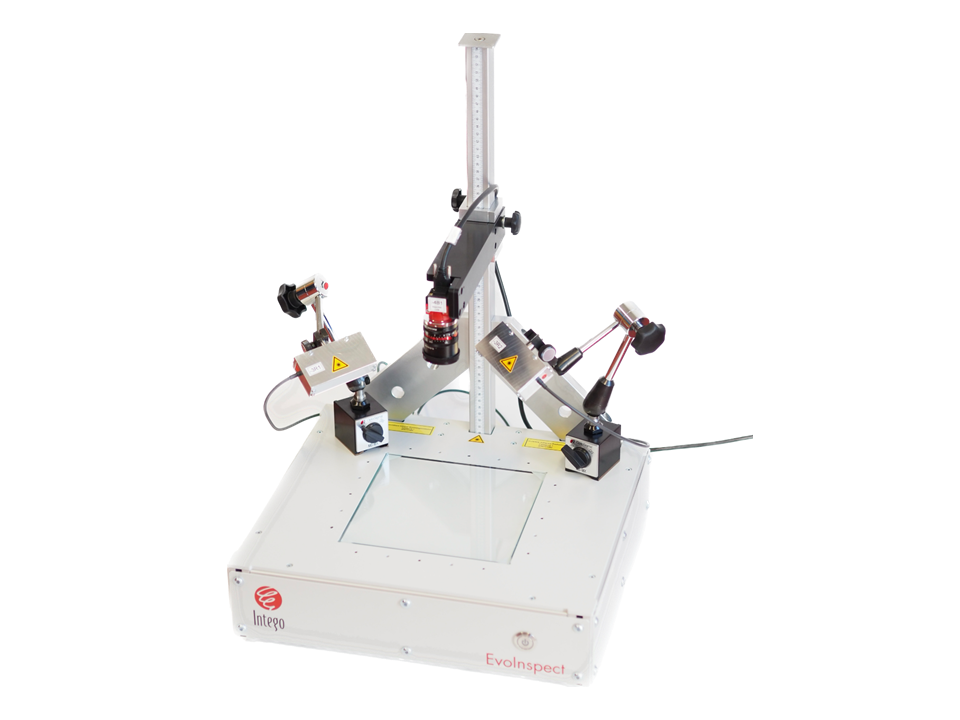

Intego is now part of the Optica network

Intego GmbH has been developing high-precision customized camera inspection systems for quality control since it was founded over 25 years ago. Over the years, the portfolio has been continuously expanded – in recent years in particular to include various systems for inspecting optical components made of glass and plastic. Current examples include systems for inspecting…

Meet EVOSYS at KUTENO

Next week you will find us at the KUTENO where we will show you our solutions for welding plastic parts. Our experts will be happy to advise you personally on the advantages and possibilities of this joining technology. KUTENO will take place from 13 to 15 May in Bad Salzuflen. You can discuss your project…